Description:

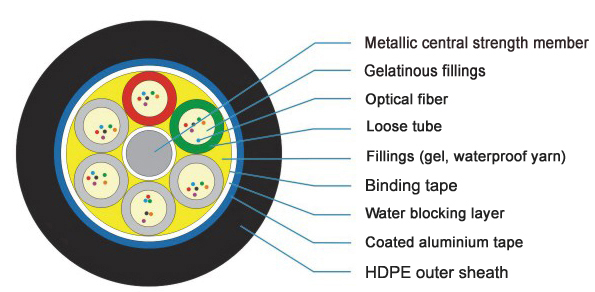

□ Six loose tubes (or some fillers) stranded around the metallic central strength member

□ The cable core is filled with cable filling compound

□ An Aluminum Polyethylene Laminate (APL) is applied around the cable core and further sheathed with High Density Polyethylene (HDPE).

□ Tubes (and fillers) are stranded around the central strength member into a compact and circular cable core.

□ Each loose tube contains secondary coated single or multi-mode fibers (2~6).

Characteristics:

□ Accurate fiber excess length ensures good performance under mechanical stress and good temperature performance

□ Materials of loose tubes are of good temperature performance and high Young's modulus.

□ Tubes, cable core and all interstices are filled with special tube filling compound to ensure long term stability in transmission for two long wavelength windows, moisture-proof and absence of longitudinal water ingress.

□ The central strength member is made of phosphatized steel wire with high Young's modulus.

□ The corrugated aluminum tape is laminated at both sides with polyethylene and bonded tightly with PE sheath. It ensures radial moisture-proof of the cable and reinforces the latter's crush resistance.

□ The outer sheath possesses good ultra violet resistant property.

Applications:

□ Outdoor communications, Long distance and local area network (LAN) communications.

Laying methods: Aerial, duct

Temperature range: -40℃~+70℃

Fiber count:2~144

Outer diameter:10.5~16.0mm

Weight:110kg~260kg |